Smart things

Small things often have a great effect. On this page you will find some solutions – solutions that will make rodmaking easier or a bit more effective.

The pictures give a first impression. If you would like to know more, you can call me and get some more pictures. I would also be happy about new suggestions.

G. Saupe´s little lathe

The two equally structured lathes for mechanics were produced in industrial quality by the company G. Saupe, Leipzig (the modern world should take those ones as an example). Both are arranged in a row, so making sleeve fits is not a problem anymore. One does the work, the other prevents the pounding.

Digital

An easy as well as cheap solution is to fix two discount digital slide gauges to the work table. So it is easier to handle the hundredth.

Milling device

To mill reel seats I use a milling device with five blades. This is clamped into the three-jaw chuck of the lathe. A special device makes it possible to mill the reel-base fit in a clean and precise way. I can run in and out of the workpiece (reel-seat) without a problem. The lathe´s speed of 3000 revolutions per minute is sufficient, thanks to the five blades of the milling device.

Frequency converter

Both lathes are driven by the frequency converter. This allows an easy and direkt setting of every (mechanically possible) number of revolutions per minute. You can also set the running clockwise and counter-clockwise or stop the device.

Lutzek

The „Lutzek“ is a self-made water-grinding-machine containing a Japanese grinding-wheel with a grain of 800. It makes the precise pre-grinding of planer knives easier. A ceramic stone with a grain of 2000 and a water-grinding stone size 6000 are quickly doing the rest. In addition, my wife is pleased about sharpened kitchen knives.

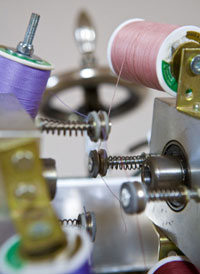

Winder

The four threaded winder was created by myself and I have been using it for a long time. A modification in the adjustments of the thread tension and the drive allows me to look at the next glueing with ease. I would be happy to answer you questions about the sources of supply of endless round belts or the used kind of thread-quality.

Oven

A copper pipe with 60mm in diameter, two heating tapes, a few wooden boards, an energy-control and a thermometer (Swiss of course) enable me to use every temperature between 20° and 200°C to dry the splits or temper the glue.

Digital weight scale

An easy way to keep mixing ratios of coating or glue that are made of two components, is to use a precise digital scale. This way you can weigh the amounts up to the tenth of a gram. Hardening and binding agent often have a different density, but in our case this problem can be ignored. Using the same amounts of hardening and binding agent, the mixture contains a higher volume of hardening agent, because it has less density. This way you get a good flexibility after glueing. That is important when glueing the sleeves.

Winding check maker

To drill hexagonal holes into either wood or nickel silver I am using hexagonal tappets existing in steps of tenth. This way you can drill one hole in key measurement of the rod, after that one hole in corner measurement and with some sensitive pressure of the vice you get the finest winding checks.

Natural root wood

If you are paying a little attention to the surrounding nature, you can find the best wood to use as a reel-seat spacer in many everyday situations.

- stag's horn sumac, lilac and laburnum are having the finest grains

- grained nodules or injection cores of the common European beech can easily compete with all exotic woods

- roots and grained nodules of birches are available for free in landscape management

Rod grill

Because my rods are dip coated (without any constructions) to get a flawless finish, I have to wind the rings around the coating.

This way it is almost impossible for moisture to get in. The winding of the rings is a much debated subject. Should colour and structure of the rings be of the same kind as the rod and therefore be almost invisible? Or should it emphasize and point out the beauty of the rod?

Actually I am a true supporter of splendid constructions.

I am winding with Gudebrod in rich colours.

The protection of the bonds is made perfect with Flex Coat. It is a coating of two components that offers best shine and protection with its mechanical qualities.

But it takes some time before you get the effect. That is why I use the rod grill. Being the main part of the device, the grill motor turns the rod with 1-2 revolutions per minute until the coating is dried up, so "bulges" at the rings are prevented.

G. Saupe's little lathe

Digital

Milling device

Milling device

Frequency converter

Lutzek

Winder

Oven

Digital weight scale

Winding check maker

Natural root wood

Rod grill